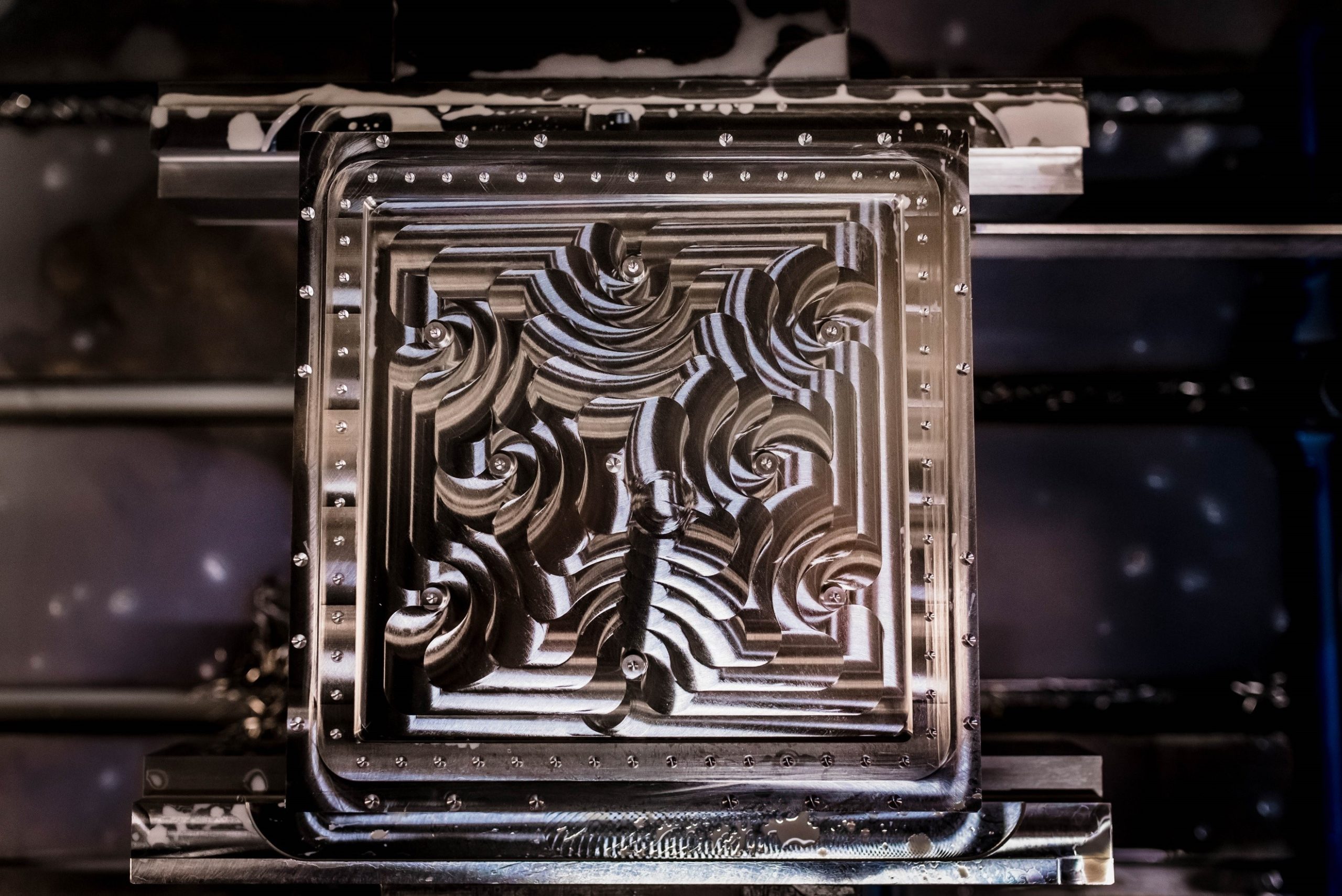

CNC Machining

We’re problem solvers. Three generations of manufacturing excellence allow us to effectively deliver virtually any machined project, from prototype parts and specialized low runs to full production runs.

From one prototype to thousands of production parts, we can help. We work with all metals, including stainless steels, aircraft aluminum, nickel-based alloys like Hastelloy, titanium, tantalum, and kover, and many more. We also machine all types of plastics and ceramics.

Our 20+ CNC machining centers that provide precision machining of metal and plastic custom parts.

Our milling machines range in size. With our largest having 120” X travel and 40” Y travel it allows us to handle some of the most extensive parts around. We also have full 4th axis capabilities in many machines. These CNC Milling machines have spindles with 12,000 RPM, High-Speed Machining capabilities, and up to 40 position ATC’s.

Our CNC Lathe’s have with bar feeders, parts catchers, chucks and live centers allowing us to turn all types of parts in a broad range of sizes.

We believe that new equipment is more accurate and faster as well as more economical for our customers and us.

Contract Manufacturing

BORG DESIGN OFFERS FULL PRODUCTION SERVICES TO DELIVER FINISHED PRODUCT IN ANY VOLUME REQUIRED.

We can provide higher volume production. Including post machining services like plating painting and heat treat. We work with Kanban’s, blanket orders and other forms of long term orders. We are happy to discuss your needs and help come up with a solution to get you the parts you need in the time frame you want.

Prototype Machining & Design for Manufacturing

GENERATIONS OF MECHANICAL ENGINEERING AND MACHINING EXPERIENCE TO HELP YOU WITH NEW PROTOTYPES AND PRODUCTS.

- Initial prototype, samples and low volume production runs.

- Working straight from models or limited dimension drawings.

- Design for manufacturing assistance and advice. To help your product be easier to produce.

- CAD & Solidworks design, including 3D solid modeling and drafting services.

- Fully outfitted with the latest technology to help bring your idea from concept to full production.

Hear what others are saying.

“Borg Design has been a valuable asset to our business. Their manufacturing quality and design for manufacturability expertise have created a unique relationship with our mechanical design department. Borg Design is genuinely a partner and is treated as an extension of our company’s metal fabrication operations. Their extensive design and metal fab experience combined with their willingness to collaborate on designs separate Borg Design from most vendors. I have and will continue to recommend Borg Design to my mechanical engineering colleagues.”

“Six months ago, we had a very complicated job that required a fast turnaround. One of our new design engineers suggested we try Borg Design. We did and were very happy with the quality and turnaround time. Since then, we’ve used Borg Design for several projects. They always produce quality parts within our time frame. They have the tools, expertise, and equipment to do jobs that other machine shops just can’t do.”

“My company has been doing business with Borg Design since the 1970s. It started with Karl A. Borg. During the time we’ve worked with Borg Design, our business has grown significantly and Borg Design has served our needs every step of the way.”

“We needed a manufacturing partner that could deliver highly engineered parts, quickly, and with very low rejection rates. Borg Design and their ISO-9001 certified processes have over delivered on all counts.”